ANALYSIS | Since 2006 when crude oil deposits were first confirmed in the Albertine Rift in mid-western Uganda, commercialization of the resource appears nearer than ever as The Independent’s Ronald Musoke found out on a recent tour of ongoing projects.

The Uganda government has always touted the oil project as one that will transform Ugandan society and the officials often point to the US$15bn windfall the country has raked-in even before oil production starts.

The government says this outlay of investments is beginning to significantly impact the country’s economy. The government adds that over the next 25 years, the oil project will provide a boost to investment in other sectors of the economy, bringing a potentially transformative impact for millions of Ugandans and the country at large.

Our four-day tour began on November 13 when journalists drawn from media houses around the country set off from Kampala for the mid-western city of Hoima in the company of George Lugalambi, the head of the African Centre for Media Excellence (ACME), officials from the Petroleum Authority of Uganda (PAU), the national oil sector regulator, and others from the Uganda National Oil Company (UNOC).

In Hoima, staff from TotalEnergies E&P Uganda B.V and the China National Offshore Oil Corporation (CNOOC) Uganda Ltd and the EACOP Company gave us an introductory overview of Uganda’s oil project; the resource inventory, where it is found, the companies involved in developing and commercialising it, how Ugandans are involved and how much investments in billions of dollars the country has so far raked-in. The official dwelt on contextualising Uganda’s oil project in relation to the global climate change and energy transition debate. They also showcased the range of oil and gas infrastructure that the country must build before “First Oil” can be realized.

Kingfisher busy

On Day-2, we drove to the Kingfisher Development Area which is perched on the southeastern shores of Lake Albert in Buhuka Parish in Kikuube District which lies inside the western arm of the East African Rift Valley.

The Kingfisher Development Area is up to 15km long in parts and 3km wide. The wells here are sunk on the shores and sink up to 2km deep under the lake. They are expected to pump about 40,000 barrels of oil per day. This particular oilfield is estimated to hold about 560 million barrels of oil in place, out of which 190 million (33%) is expected to be tapped over the next 20-25 years.

The Kingfisher Development Area has since 2013 been developed by CNOOC Uganda Ltd, a subsidiary of the China National Offshore Oil Corporation, China’s largest producer of offshore crude oil and natural gas. CNOOC officials, most of them Ugandan, showed us ongoing oil development activities, including construction of a Central Processing Facility (CPF), and drilling of wellpads holding 31 production and water injection wells.

The Kingfisher Development Area has four well pads (1,2,3 and 4A) and the central processing facility, explained Zakaria Lubega, the Corporate Social Responsibility Manager at CNOOC Uganda Ltd as journalists crammed around him on a viewing platform near the top of the escarpment.

“The well pads will be linked by flowlines that will pick up the unprocessed fluid (crude oil mixed with sand and water) and take it to the CPF for processing,” Lubega said before we got back into our vans and moved closer to observe the on-ground activities near the Lake Albert shores.

My last visit here was two years ago. Apart from the camp which was hosting a few maintenance workers, there was hardly any activity back then. This time, I found plenty going-on, with hundreds of workers dressed in colourful coveralls and PPEs—even with the unforgiving sweltering temperatures.

Many of the workers were perched atop steel structures, others were on the ground doing final touches on pipes which we were told will soon be joined together to make a maze of 16-18km of in-filed flowlines. These pipes will pick the fluid from the wellpads to the central processing facility hub for processing.

Another 46km of feeder pipeline will then transport crude oil from the CPF in Buhuka up the imposing escarpment and onto Pump Station-1, the starting point of the EACOP at Kabaale Industrial Park in Hoima District.

Dickson Asiimwe, a Piping Engineer and Joseph Omaswa, a Communications Engineer from CNOOC’s surface engineering team explained how the fluid containing crude oil flows from the oil wells to the central processing facility, gets separated from the impurities (water, sand and other sediments) before it’s pumped up the escarpment to Kabaale.

“The process starts from the well pad where the oil is picked; it then gets to the CPF through in-field flowlines. Then the oil goes through the processing and separation stage where you have the crude oil alone, the gas alone and the water,” Omaswa explains.

At a nearby rig, youthful Annita Komugisha, a junior drilling engineer, says CNOOC is currently drilling six development wells that will be part of the 31 wells that are to be drilled in the Kingfisher Development Area.

Komugisha, a graduate of Petroleum Engineering and Environment Management from Mbarara University of Science and Technology, who has been working here since 2022 says she is stationed at well pad-1, one of the three active well pads.

“We started drilling in Kingfisher on Jan.24, last year, after the spudding ceremony. We started with well pad-2 and quickly moved to well pad-3 and we are now on well pad-1,” she says. Komugisha says drilling operations at Kingfisher emphasise safety and environmental conservation.

“On some rigs elsewhere in the world, you would expect a person to stand on the platform near the top of the rig to be able to move pipes during the drilling operations,” she says, “Here, we have an iron Derrickman; this has enabled us to enhance our safety.”

She explains that having an iron Derrickman is an enhanced safety feature which makes the LR-8001 rig semi-automated and able to perform with human help but also without such assistance.

CNOOC says this brand-new state-of-the-art rig was specially designed for the Kingfisher oilfield and is the strongest that has been used in the country to date consuming about 6MW of electricity. It has the capacity to drill up to 8km deep, with noise suppressing technology making it more environmentally friendly.

Komugisha says the Kingfisher project neighbours a settled fishing community whose environment must not be disrupted. “For instance, when the rig is powered at night, it uses dim light that is configured so as not to blind people,” she says, “We do not use floodlights.”

“We took into consideration the fact that we have a fishing community next to us,” she says, “and the light doesn’t scare away the fish in the lake.”

“We are currently running a bottom hole assembly to continue our drilling operation but we are able to have this conversation almost as if there is nothing going on behind us,” she says as the rig hums behind us. “If you visited most drilling rigs elsewhere, we wouldn’t have this conversation without me screaming but all this is possible because of the noise mitigating measures put in place.”

Komugisha also notes that all Kingfisher’s reservoirs (oil wells) are offshore (underneath Lake Albert) but the operator is conducting onshore drilling. “We are accessing the reservoirs from land platforms,” she says. “We are accessing the reservoirs via directional drilling; the drilling starts on land, vertically drilling until you reach a kick-off point within sub-surface where you begin making an inclination until you reach the target that you are aiming at.”

She says the well pad also has the production zone as well as administration units and a small area for the collection and handling of drilling waste which is then transported to the nearby Luweero Industries Ltd, a subsidiary of National Enterprise Corporation (NEC)–the commercial arm of the Uganda Peoples Defence Forces which has gone into an oil waste management partnership with HBP, a Chinese affiliated firm.

Tilenga equally busy

On Day-3, we drive on the first-class Hoima-Buliisa-Wanseko tarmac road to see the bigger mid-stream Tilenga Project which is being developed by French super major, TotalEnergies, under its local subsidiary, TotalEnergies E&P Uganda B.V.

The Tilenga project alongside the EACOP have come under sustained attack from conservationists because some of the oil wells are located within Murchison Falls National Park, one of the country’s oldest, largest, most diverse and most visited conservation areas.

It is renowned for its irreplaceable biodiversity and unparalled natural beauty. The park is home to 76 species of mammals–including elephants, lions, and giraffes and over 450 bird species, making it a remarkable, and unique, irreplaceable home. The park is also home to the Murchison Falls-Albert Delta Wetland system, a Ramsar site of international importance. The Ramsar site is an important spawning ground for the Lake Albert fisheries.

When TotalEnergies began drilling its oil wells on June 28, last year, conservationists were alarmed saying the national park would come off worse. But TotalEnergies said the drilling rig in Murchison Falls National Park is environmentally sensitive. Besides the rig being painted with a beige colour to blend with the surrounding savannah grasslands to reduce the impact on wildlife, TotalEnergies said its activities would only affect 0.003% of Murchison Falls National Park.

The Petroleum Authority of Uganda also defended TotalEnergies saying the French firm has innovative technologies and environmental-conscious practices including rigs designed to minimize the environmental footprint, ensure a positive impact on the ecosystem.

Like the ramp-up in activity at CNOOC’s Kingfisher Development Area, the scale of activity at Tilenga is probably three times as much. Two years ago, when I visited the project, local contractors were clearing bushes and moving millions of cubic metres of earth in preparation for the construction of the camps for the workers.

Two years later, I found a maze of overhead steel structures stretching as far as the human eye can see. Like at Kingfisher, the contractors were busy putting enabling infrastructure in place. A CPF which is able to process 190,000 barrels of crude oil from the oil fields is taking shape.

Mazen Abi Azar, the Construction Manager who is also responsible for safety and environment on site told us that they are concurrently drilling eight well pads north of the Nile and 21 well pads in the south. From these various wellpads will be a network of in-field pipes which will connect to the CPF, he said.

“The central processing facility is the hub of the project; this is where we treat the oil; we separate the oil and we get it ready for export with a feeder line.”

Mazen said they are working on two main packages; the first package has to do with enabling infrastructure which is now ready. The second package has to do with building the CPF, fixing the flow lines and surface work for the wellpads. The enabling infrastructure phase has involved moving about 3 million cubic metres of earthworks, constructing roads, warehouses, and the drainage system.

Solomon Balemezi, the Civil Works and Structural Supervisor at the Tilenga Industrial Area chipped in noting that at the CPF, water which is a waste product will be pumped back into the injection wells so it can be used again to produce more crude oil. But the sand and other solid sediments will undergo treatment before being disposed of.”

“Right now, there are a lot of civil works going on; installations of structural steel as well as some of the equipment which are crucial for the oil production,” said Balemezi.

“We are in the engineering, procurement, supply, construction and commissioning. The engineering is completed, the procurement is at the tail end and right now we are in the construction phase and after that we will get to the commissioning phase.”

Gloria Sebikari, the Corporate Affairs Manager at PAU explains that the Kingfisher and Tilenga projects are hundreds of kilometres apart yet for Uganda to produce and commercialise its oil resources, the two projects must have similar facilities in place.

“When the oil comes out of the well pads, it will be transferred to the CPFs through infield flowlines. For the Kingfisher project, we have 16-18km of infield flowlines to connect to the different wellpads to the CPF so that the oil is collected there. For the Tilenga project, it is close to 160km of infield flowlines. At the CPF, the oil will be processed before being sent to Pump Station-1, which is 95km away.”

EACOP’s Kilometre-0

On Day-4 we headed to Kabaale Industrial Park at Nyamasoga, Buseruka sub-county in Hoima District. On a piece of land, which is about 29sq km, is where Kabalega International Airport is nearing completion. It is also where another piece of complex infrastructure is taking shape.

This is the starting point of the famous 1,443km long electrically heat-traced EACOP. Here, we are in the company of Hadi Watfa, the Delivery Manager of Above Ground Installations who also goes by a local alias Semaganda Akiiki. Watfa is a Lebanese petroleum engineer who over the last 35 years has worked on similar oil infrastructure projects in both the Middle East and Africa.

He says there are 47 nationalities working on the project. “At the moment, we have 1347 staff of whom 92% are Ugandans,” he says. Eventually there will be up to 12,000 people working on the EACOP when construction activities are ramped up.

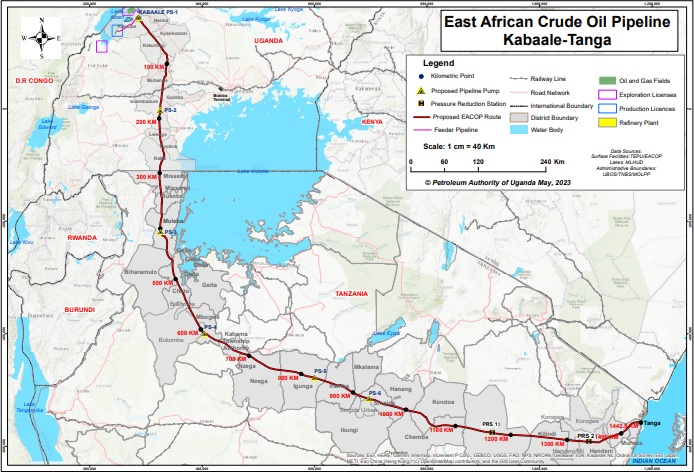

He takes us to a clearing he says is about 75,000 sq metres and begins to explain what this place will look like under two years’ time. “This will be the starting point or “Kilometre-Zero” of the 1,443km EACOP,” he says.

This is where all the oil from Kingfisher and Tilenga CPFs will be brought and mixed or co-mingled, metred and then transported via pipeline to the Tanzanian port of Tanga. “We will collect crude oil from Kingfisher and Tilenga (230,000 barrels at peak) and take it to Tanga where the storage facilities which will hold about two million barrels of crude are being constructed,” he says.

“To push this crude oil from where we are right now through 1443km is not an easy job and that is why we have to use pumps,” Watfa explained, indicating that this is where the pipeline’s so-called Pump Station-1 will be based. The second pump station will be in Sembabule, 180km from here. Watfa goes into the complexity and sophistication of Uganda’s pipeline.

He says he has worked on pipelines since 1993 in Nigeria, Qatar, Saudi Arabia, Iraq and China but he has never come across a project that is as sophisticated as the EACOP.

“I have never faced such an extreme case of care of a project. In Nigeria, where a similar project was built, it was done with eyes closed,” he says. Yet Watfa appears unfazed, jolly and talkative. He says the pump station will have an electricity substation as well as a control room to ensure a 360̊ view of the EACOP.

“This is a sophisticated system to control the pipeline to ensure that the oil flows smoothly to Tanga,” he says. From the clearing we move to the pipe corridor where we observe the intersection of both the EACOP and feeder pipelines coming from both Kingfisher and Tilenga CPFs. Watfa says the pipe corridor has pipes coming in from the East through Tilenga and another is coming from the West through Kingfisher before joining at the Export Pump.

Moses Kirumira, the Deputy Construction Manager of EACOP also says the export pipeline is “the most innovative and most intelligent pipeline” in the world. He says the stringing of the pipes is, for instance, being done according to the different sections of the route.

“It may look like just putting the pipes on the ground but you have to understand which pipes you are laying and why you are putting them in that particular location,” he says, “Sometimes the pipes have be bent at different angles because we are trying to minimize our impact on the environment so we bend the pipes according to the terrain.”

How much time left?

The government has repeatedly told the public that Uganda will sell its first batch of petreluem by the end of 2025. Although there is a lot of work ongoing across various critical infrastructure, it still looks like a tall order. So, The Independent asks Watfa, how much time he has to complete this particular piece of infrastructure–Pump Station-1.

“From today, in 16 or 17months’ time we should be done with the construction of Pump Station Station-1,” he says. That pushes the project to 2026.

But another three months will be dedicated to a pre-commissioning exercise where every subsystem will be tested, he adds. “For instance, we have to make sure that the piping subsystem is working; to ensure that it has no leakage or any deficiency. The same will be done to the electrical installation and telecommunication subsystems.”

“After the precommissioning stage, we will have another three months to do the commissioning where will ensure that all these subsystems are work and communicating with each other,” Watfa, says.

From our four-day interface with various contractors of the projects, one gets the sense that even if they respect the government’s ambitious timeline for “First Oil” scheduled for the last quarter of 2025 – in reality that appears like a long shot.

Indeed, Ruth Nankabirwa, Uganda’s energy minister appears to be re-adjusting the government’s timeline for first oil – again. Speaking to the Financial Times, a British newspaper, on the sidelines of the recent COP29 Climate Summit in Baku, Azerbaijan, Nankabirwa said Uganda’s oil project has run into financing hurdles because of “climate change issues.”

This, Nankabirwa noted, has meant that the project’s financing has had to be renegotiated. As such, the equity-debt split has been revised from the original 40/60 to 52/48. She told Financial Times that the stakeholders are expected to receive the debt financing from several international institutions, including the Export-Import Bank of China, this December.

“If it wasn’t for the injustice that has been done to it, we would be talking about seeing our first oil in 2025. But because of the campaigns against it, we are not going to see the first oil next year. So, we expect to run into 2026-2027,” she said.

The Independent Uganda: You get the Truth we Pay the Price

The Independent Uganda: You get the Truth we Pay the Price